I. Project Background

A well-known listed beer company is approved by the board of directors to build MES system in a province in southern China. Traceability of production process, systematization of process and high-quality products have always been the primary goals of this manufacturer. They need a platform that can be connected to the current ERP system and existing equipments, provided that no additional infrastructure is needed. The management of the company finally selected TrakSYS to build its powerful and flexible operation and management platform, which can guarantee that the right data will be provided to the right people at the right time.

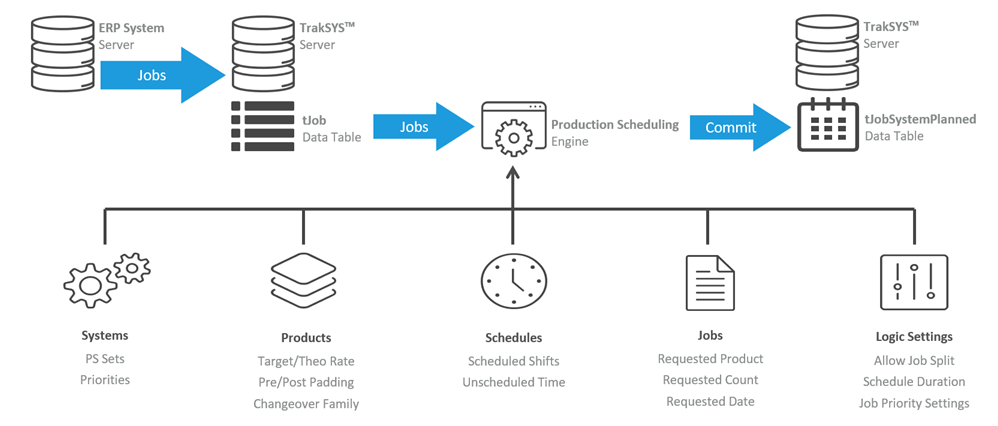

As we all know, MES can provide enterprises with management modules including manufacturing data management, planning and scheduling management, production scheduling management, inventory management, quality management, procurement management, shop floor data integration analysis, IT level data integration and decomposition etc., and build a solid, reliable, comprehensive and feasible manufacturing collaborative management platform for enterprises.

This customer implement this MES system is aim to:

(1) Build a basic platform for data collection of factory production management system, with good expansibility;

(2) Build a comprehensive and complete product tracking system;

(3) It is developed based on Microsoft .NET platform, supports mainstream databases such as Oracle/SQL Sever, adopts B/S system structure, and is easy to install and upgrade;

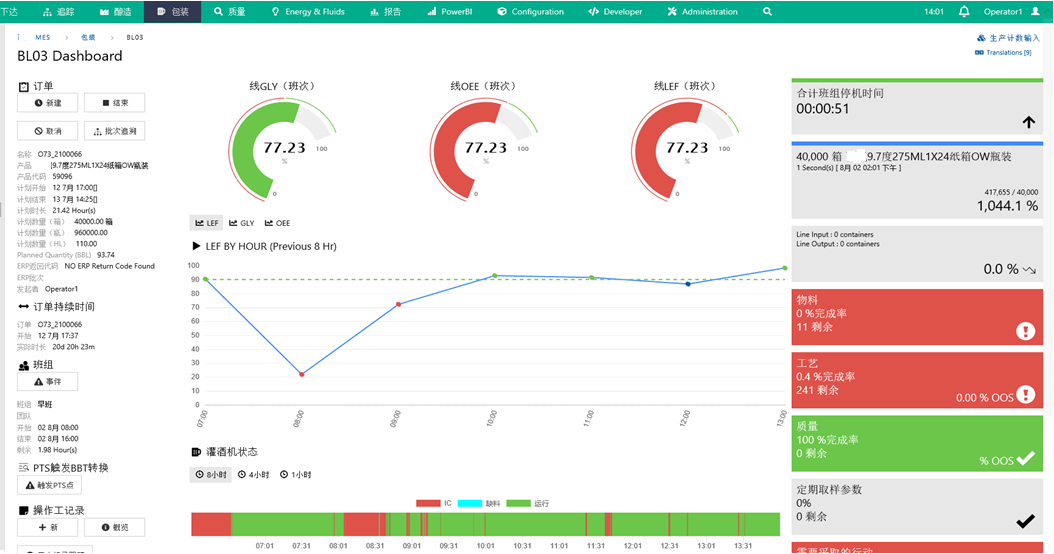

(4) Customized factory information platform Portal, through the WEB browser, can grasp the real-time information of the production line anytime and anywhere.

II. Solutions

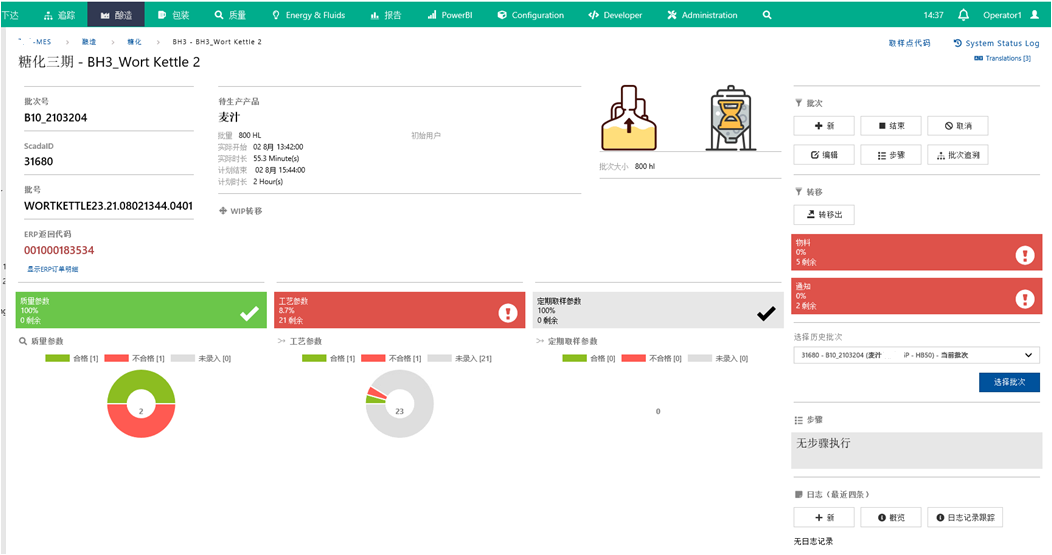

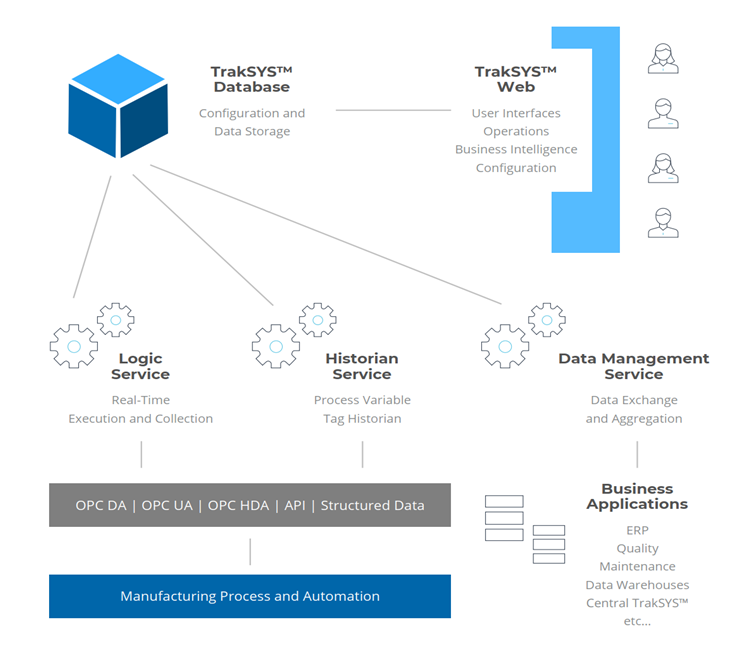

The MES system is developed and implemented based on TrakSYS system, and the construction of TrakSYS system needs three main elements, namely relational database, system service and Web service, on which data interaction and page display can be carried out. These elements can be placed on a single server or distributed on multiple servers simultaneously. TrakSYS supports deployment in virtual environment and cloud, but it must run in standard Windows Server environment. The system covers many fields such as enterprise resource management, product information management and automatic function management, and breaks the boundary between traditional IT and OT, so that it can serve users better.

III. Project Results

After deployment:

(1) TrakSYS process management, traceability management and electronic records greatly reduce product defects caused by poor resource quality, manufacturing process errors and human errors;

(2) Creating a real-time, agile, efficient and ready-to-use enterprise-level information flow, which can be continuously improved through wise decision-making;

(3) Perfect workflow management greatly shortens the process lead time, reduces shifts and equipment conversion, and minimizes the interaction between manual operators with systems and data;

(4) The manufacturing process is improved, and the production cost is greatly reduced on the premise of complying with various compliance requirements.