In today’s complex economy, information is the key to business success and profitability. OPC technologies were created to allow information to be easily and securely exchanged between diverse platforms from multiple vendors and to allow seamless integration of those platforms without costly, time-consuming software development. This frees engineering resources to do the more important work of running your business.

|

|

With the maturity of OPC technology, the application of OPC technology and products at home and abroad has been raised to a new height. At present, the application fields of OPC products are extremely broad, and energy, oil and gas, medicine, industrial manufacturing, etc. have all adopted OPC and obtainedrespected.As a senior distributor/agent in the field of industrial automation, our team has a deep understanding and rich practical experience of OPC products and related technologies.Whether it is product selection or implementation design, we can provide you with a professional, one-stop perfect experience.

I. KEPWARE

|

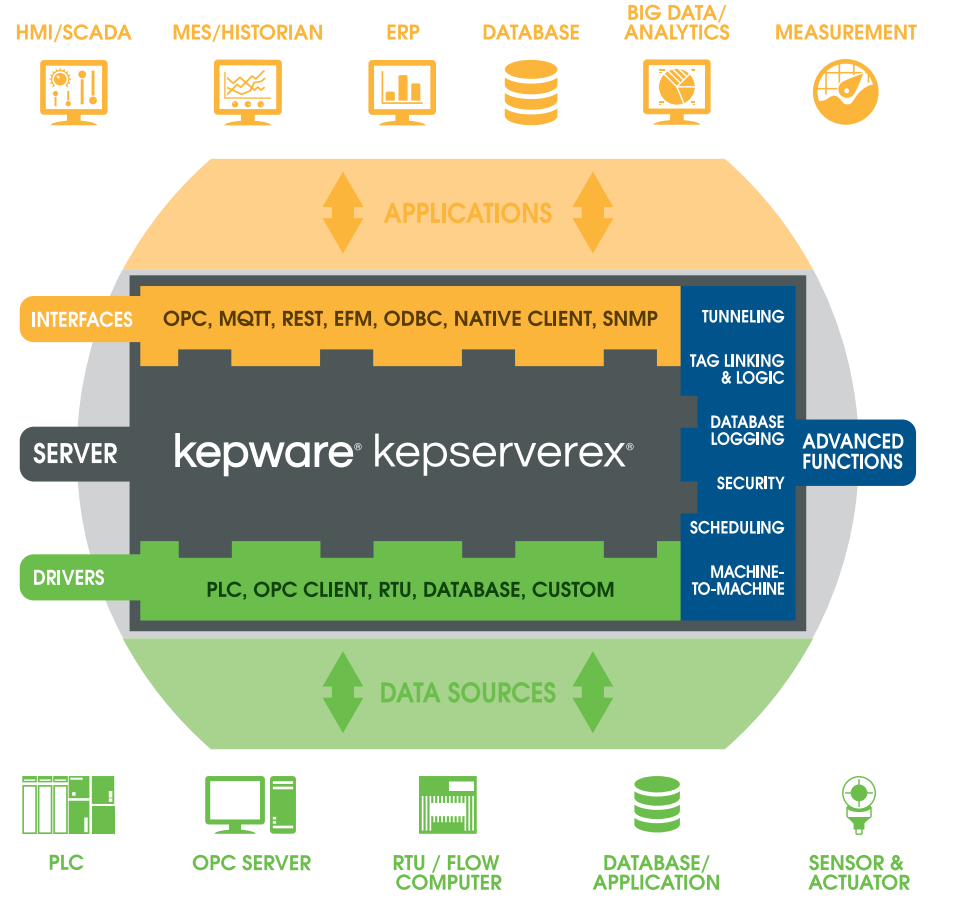

KEPServerEX is the industry’s leading connectivity platform that provides a single source of industrial automation data to all of your applications. The platform design allows users to connect, manage, monitor, and control diverse automation devices and software applications through one intuitive user interface. KEPServerEX leverages OPC (the automation industry’s standard for interoperability) and IT-centric communication protocols (such as SNMP, ODBC, and web services) to provide users with a single source for industrial data. The platform is developed and tested to meet our customers’ performance, reliability, and ease-of-use requirements.

|

Kepware will offer you:

- Connectivity

KEPServerEX offers the broadest range of drivers available, supporting current and legacy devices across various verticals within the Industrial Automation Industry. Drivers support a variety of wired and wireless networks including Ethernet,serial, and proprietary networks and various telemetry mediums. KEPServerEX provides connectivity to datas, custom software applications, and other OPC servers, and supports simulation for implementation and testing prior to deployment.

- Optimization

Through data conditioning and reduction, customized load balancing, and protocol-specific communicationsoptimization, KEPServerEX improves communications and reduces network and device load. It also features Machine-to-Machine ing and redundancy.

- Aggregation

KEPServerEX maximizes data applications by supporting connections to thousands of data sources and providing information to hundreds of applications through a single architecture. This eliminates the need to purchase, operate, and maintain disparate applications for discrete connectivity.

- Accessbility

KEPServerEX provides accessibility to leading automation, Big Data, and analytics software via OPC, proprietary protocols, and IT protocols (including MQTT, REST, ODBC, and SNMP). Historical data is accessed through OPC standards, trend logs, and Electronic Flow Measurement (EFM) for hydrocarbons.

- Security

Tools within KEPServerEX expand administrators'abilities to control user access and regulate browse/read/write privileges for secure data communications. KEPServerEX supports a number of secure client standards including SNMP, OPC, and HTTPS to further restrict access to the server, as well as a number of secure device protocols to meet the requirements of DNP3, SNMP, and OPC UA data sources.

- Diagnostics

KEPServerEX provides robust communications diagnostics to easily isolate and troubleshoot device and application communications.

II. OPC ROUTER

|

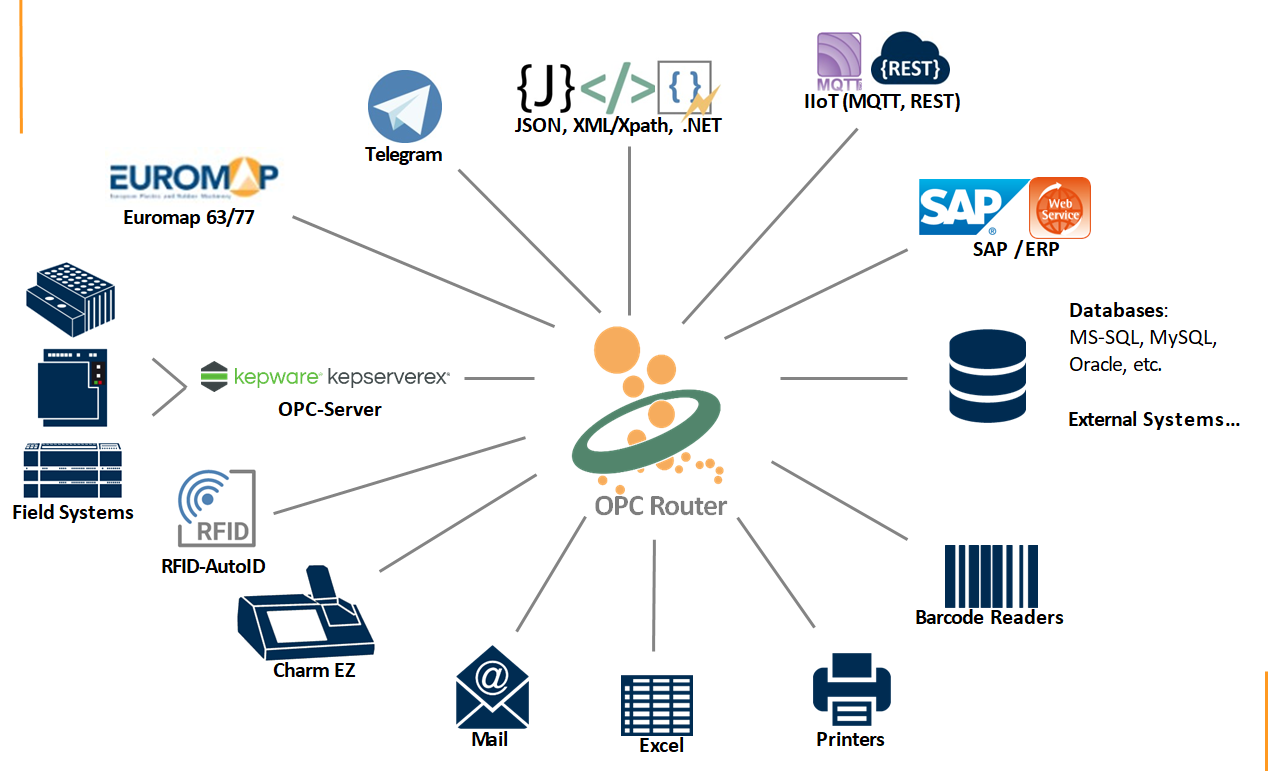

The continuous optimization and automation of your production processes is the decisive key to the quality of your products, the efficiency of production as well as the success of your company. OPC Router replaces old communication channels – up to the complete integration of PLC (Programmable Logic Controller), DCS (Distributed Control System), SCADA, MES (Manufacturing Execution System), SQL Server, label printers, email server and ERP systems. The Router as a central communication platform offers automated data exchange by integrating all systems and stand-alone solutions from the sensor to the cloud. |

By recording your process data, you have a continuous overview of your production. The application possibilities are almost unlimited and can be implemented by yourself. We offer you comprehensive training for the application scenarios and use cases for your Industry 4.0 production process. The OPC Router works like a universal translator for your systems. It enables the communication of all systems and protocols and can be easily integrated into existing automation and production environments. With the appropriate Plug-ins, you can connect different automation and IT systems with each other by drag & drop, thus building your Industry 4.0 structure:

- OPC Router - Visualization of data transfers

- Standard interfaces for data exchange

- State-of-the-art middleware for IoT and Industry 4.0 projects

- Implementation of different connection types via powerful modular Plug-ins

- Recording of process values, production figures, malfunction times and reasons for data loss as a basis for your production optimization

- Event-driven connectivity between automated systems

- Creation of individual connections and transfers via user-friendly graphic configuration

Contact us immediately to get the right product for your applications!