I. Principle

The remote measurement diagnosis system is a special software system used in the field of natural gas pipeline transmission and natural gas trading and handover. The monitoring and management object of the system is the standard configuration natural gas metering circuit widely used in the field of natural gas;

By collecting, analyzing and processing the key operation data of the natural gas metering circuit, this system can reflect the operation status of each key instrument in the metering circuit in real time, thus reflecting the metering error of the metering circuit at the first time. By analyzing the key historical data of each instrument, the system can obtain the historical running status of the instrument, thus finding the change and trend of the measurement accuracy of the instrument, and then actively sending out suggestions for instrument diagnosis and maintenance, and then reducing the cost accordinlgy.

II. Applicable Scenarios

1. National Gas Pipeline Transportation Trunk Line and Branch Line

2. Provincial/Municipal Gas Pipeline Transportation and Gate Stations

III. Project Reference

1. China Petroleum West-East Gas Transmission Phase I & Phase II

2. Fujian Metrology Institute

3. Zhejiang Ningbo LNG

4. Uzbekistan Remote Diagnosis System

5. Horgos Remote Diagnosis System

6. Central Asia - Remote Diagnosis System of Ultrasonic Flowmeter

7. Measurement Remote Diagnosis System of Wuwei, Jinchang Natural Gas Offtake Station of West Second Line and Yongdeng Refined Oil Offtake Station of Shuanglan Line

8. Measurement Remote Diagnosis System of Beijing Natural Gas Pipeline

9. Measurement Remote Diagnosis System of Guangdong Natural Gas Pipeline

10. Measurement Remote Diagnosis System of Jiangxi Natural Gas Pipeline

......

......

IV. Features of the System

The technical implementation of this system adopts a variety of new technologies, data analysis and data management processes, including:

1. Analysis and diagnosis technology of running status of metering instrument based on management process of natural gas standard metering equipment

2. Realization of data analysis, management and storage technology based on relational database and time series database

3. Data report and report management system

4. Remote system platform access function based on B/S architecture

Among them, a variety of innovative and applied technologies and algorithms (compatible with Daniel,Elster,Sick, RMG and CNCVIS diagnostic algorithms that have been verified by engineering) are adopted in the implementation of instrument condition analysis and diagnosis technology and data analysis and management technology.

V. System Screenshot

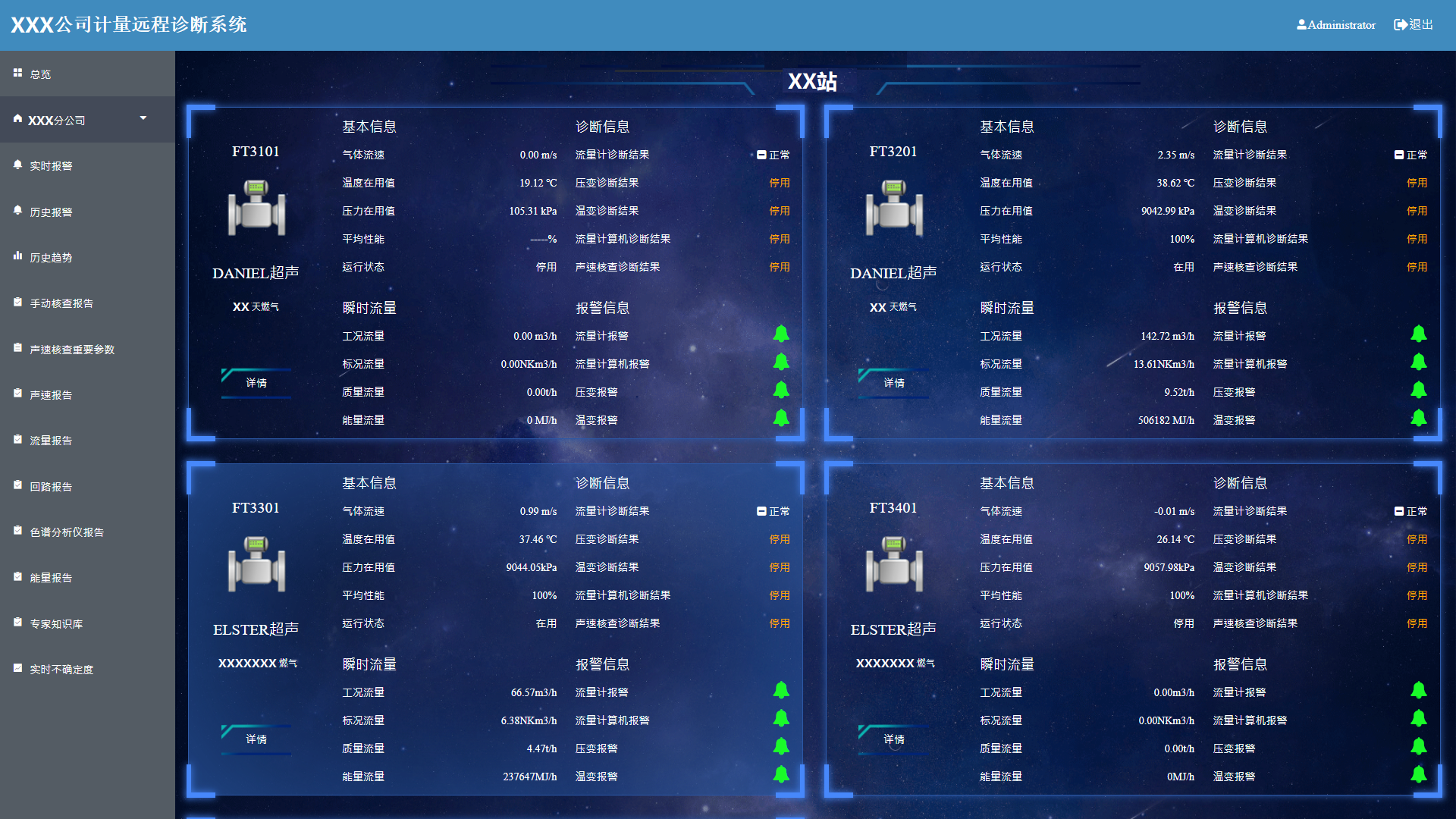

1. General Drawing of the Station

This overview diagram is an important display diagram in CBM system. It can display the working status of each metering circuit in the current station,

the working status and alarm status of each equipment, and check the circuit.

2. Loop Verification

The remote diagnosis system provides a comprehensive status checking function of the metering circuit, which is comprehensive and aims at the status checking of the entire metering circuit, including ultrasonic flowmeter, flow computer, chromatographic analyzer, temperature transmitter, pressure transmitter, straight pipe sections before and after the flowmeter and natural gas rectifier, etc. The remote diagnosis system realizes the diagnosis of flowmeter loop running status, pipeline dirt and pipeline and rectifier plug through the intelligent diagnosis technology of ultrasonic flowmeter, and generates the diagnosis report of metering loop.

3. Diagnostic Verification Function Diagram

The remote diagnosis system automatically collects all kinds of measured values of ultrasonic flowmeter, chromatographic analyzer, temperature transmitter and pressure transmitter in each metering station and each metering circuit online, and performs real-time sound velocity calculation according to AGA10, which is used to compare the deviation between theoretical sound velocity and measured sound velocity. In addition, the remote diagnosis system automatically checks the sound speed/flow rate of the in-use metering circuit every day according to the method of G1030《Verification Regulation of Ultrasonic Flowmeters》, and generates a diagnosis report from the diagnosis result, giving a warning when there is an abnormality.