(A) Visual Management System

Visual management is a kind of management method that uses various visual perception information with intuitive images and appropriate colors to organize production activities and achieve the purpose of improving productivity. It is also a scientific method to manage by vision. The purpose of visualization is to show most potential anomalies of the factory intuitively and clearly, and to make the requirements and intentions of managers visible to everyone as much as possible with the basic principles of openness and transparency, so as to promote self-management and self-control.

Visual management system is an indispensable part of any modern enterprise, which is closely related to our production and life. On the one hand, it provides all-round visual guidance for staff and facilitates identification; On the other hand, it further explains the danger and function of the main equipment, and plays a role in preventing hidden dangers and avoiding risks. In the constant and repeated working environment, workers are most likely to ignore the confirmation of operation links, the confusion of operation sequence, the neglect of potential operation risks, and the formation of potential risk sources. The visual management system is just to solve these problems in production:

1. The visualization system has high real-time performance, and can display important information such as the running status of various systems and equipmenst, production indicators, etc. in real time;

2. The visualization system is highly indicative, and can synchronously display the interaction between subsystems. The production steps, especially in some complex production factories, can effectively guide the production status and direct customers to make arrangements and adjustments;

3. The visualization system is highly analytical, and can synchronously analyze real-time data, production data and display various analysis charts;

4. The visualization system has high integration, which can simultaneously collect data from all kinds of equipments, systems, PLC and databases, integrate and display them in the interface;

5. The visualization system is highly customized, and can be customized and developed according to the customer's needs and production process, completely meeting the overall demand of customers for production;

|

|

|

(B) Customized Management Platform

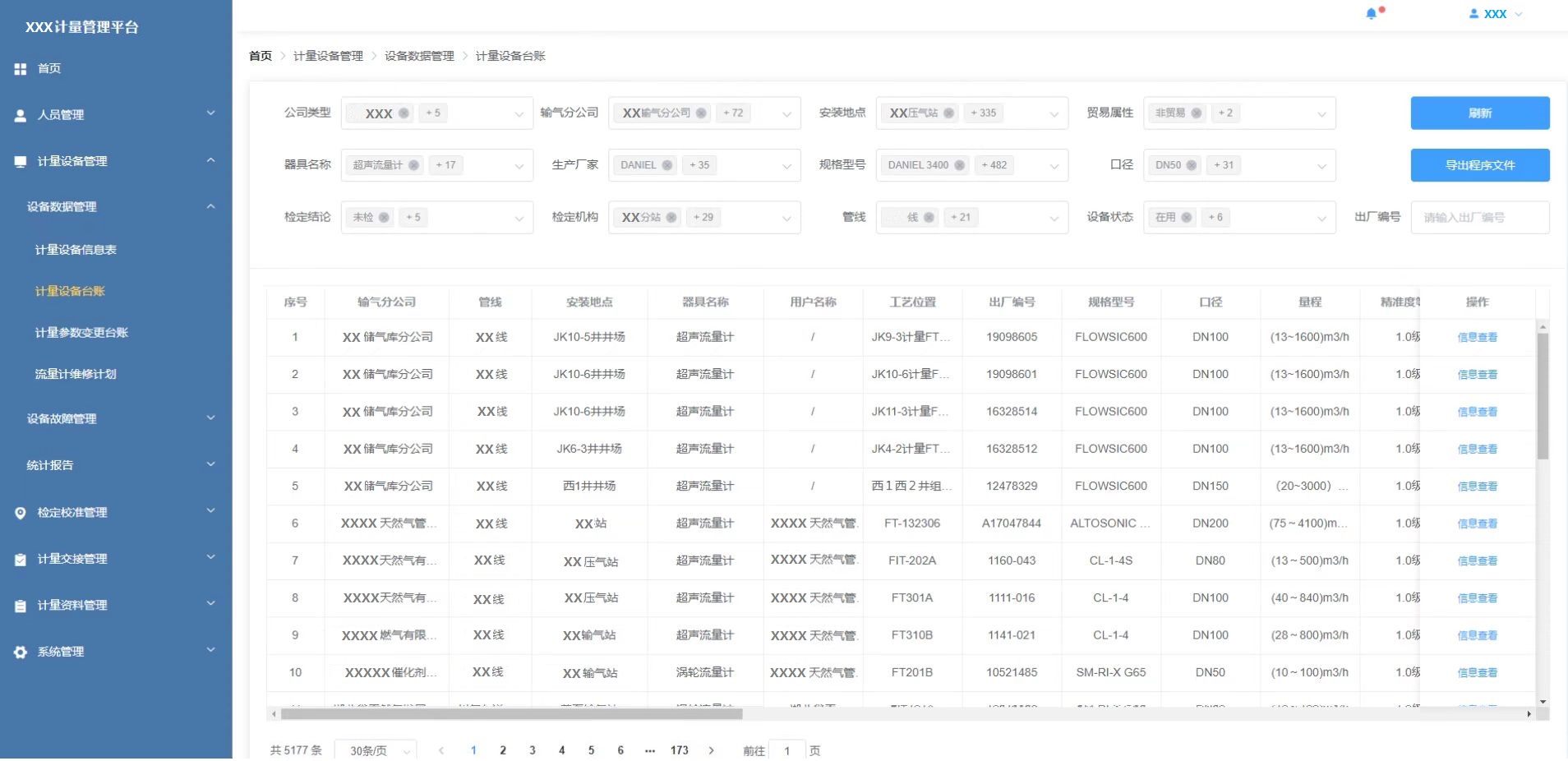

Allied Solutions (Tianjin) Automation Co., Ltd. has rich experience and strong technical strength in the design and development of personalized systems. We have customized and developed management systems for many customers in the energy industry and pharmaceutical manufacturing industry, including personnel management, equipment management, process management, operation management and system maintenance. Combined with the advantages of the current management model, we can clearly display the equipment status, production process, forms and performance in real time, highlighting the differences between the objectives and the status quo.

......

Equipment Management: Provide a unified visual management platform for production, transportation and inspection, and make three-dimensional modeling and virtual presentation of the factory environment, equipment, pipelines, personas, etc. With three-dimensional visualization technology, integrate business system data such as equipment assets, production operation, safety monitoring, etc., and manage the whole life cycle of assets, monitor the state and performance around the equipment, and visually display and apply the production and operation data;

......

Operation: Combine the customer's business scenarios, integrate the index data of various business systems, provide various normative visualization capabilities, and at the same time, build the intelligent operation center of the factory with the help of new digital technologies such as Internet of Things, big data and artificial intelligence;

Process Management: Based on the unified platform interface, the monitoring data scattered in various systems are accessed and integrated to form a unified production monitoring platform, and the linkage presentation and quick positioning of monitoring alarms are carried out based on the three-dimensional scene, and the alarms are intelligently displayed according to the alarm equipment, alarm positions, alarm events, etc. At the same time, the knowledge base can be associated for alarm disposal;

......

Customized system meets the unique management needs of enterprises, and its implementation greatly improves the transparency of enterprise operation and management, which brings a strong competitive advantage to enterprises:

(1) Real-time control of various indicators in production links, making decision-making more efficient;

(2) Deeply understand the dynamic status of enterprise operation, and help dig out the potential problems of supply chain;

(3) Integrate the production process, significantly improve the production index and process flow through the combination with MES system;